When comparing EPDM roofing VS TPO, it seems like EPDM roofing will always win. Contractors highly recommend this roofing because of the cost-efficiency. But, EPDM roofing is not always the winner of single-ply flat roof membranes. TPO roofing also offers many various benefits regardless of the additional cost for the property owners.

A side-by-side comparison between TPO VS EPDM RV roofs will help the property owners make the right and proper decision for the property they own.

EPDM Roofing

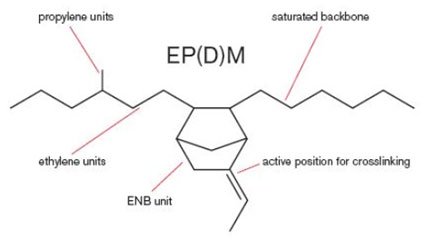

EPDM stands for Ethylene Propylene Diene Monomer, also check EPDM Wikipedia. EPDM roofing manufacturers combine recycled rubber materials from boots, old tires, and other sources to create the material. Then, they mix slate and sawdust to add strength and density.

And last, they use a printer-style material flattener to get rubber roofs ready for installation after quality checking. Contractors always suggest EPDM vs. TPO because it is effective in costs. Rubber roofs cost around $0,4 to $0,8 per square foot. If you immediately need a single-ply solution, this material is a perfect option for you.

Most property owners find value in EPDM roofing. The manufacturers of this roofing obey ASTM D4637 when they are producing the materials of the roofing. This makes sure that the rubber roofs will withstand hail storms and troubling weather conditions. This is why the increased durability can lengthen the roof system’s lifespan and, ultimately, the property as a whole. Moreover, it is easy to install EPDM roofing.

However, EPDM roofing does not look elegant since it is made from rubber materials. The most affordable materials are only available in black. You might want to consider having this kind of roofing for you who want decorative roofing for your property.

TPO Roofing

TPO stands for Thermoplastic Polyolefin. The best TPO roofing manufacturers improve on EPDM roofs with polymerized polypropylene and ethylene-propylene rubber. Besides this base material, the manufacturers strengthen the material with fiberglass and talc.

Fiberglass is a tough material asphalt and used by the manufacturers of architectural shingle roofs to improve the lifespan and the durability of both materials. This is why TPO roofing has the same strength as special shingles, which rival or exceed steel durability.

The manufacturers of TPO roofing obey ASTM D5338 standards to make sure that the roof is resistant to hailstorms, rainstorms, and bad weather. When it comes to EPDM roofing vs. TPO roofing, TPO roofing is more beneficial in durability, additional UV protection, and curb appeal.

It is because talc and fiberglass add better longevity and durability to the TPO roofing. Moreover, it is available in various colors so that you can choose the one that is suitable for your property. TPO roofing in bright colors makes sure they offer excellent UV reflective capability improving property insulation.

Above is the side-by-side comparison between TPO roofing and EPDM roofing. So, which is one meets your needs?