Understanding metal roof purlins spacing is key for a strong roof deck. My construction experience shows purlins are vital for a solid roof. They are the main support of any good roofing system.

Purlins spread roof loads evenly across the structure. They are usually made of galvanized steel, which is very durable. The right placement of purlins is essential for a strong roof.

In this guide, I’ll cover all you need to know about purlin spacing. It’s for both pros and DIYers. Knowing these details will help you build a roof that lasts.

Steel purlins can last up to 50 years with care. Cold-formed steel is the best for modern roofs. The right spacing helps your roof handle snow, wind, and more.

I aim to make metal roof purlins spacing easy to understand. I want to share useful tips to improve your roofing skills. Let’s explore the key details for a strong roof structure.

Read also: Does Roll Roofing Need Underlayment?

Understanding Purlins in Metal Roofing Systems

Purlins are key in metal roofing, providing vital support. They help spread the roof’s weight evenly, ensuring the building stays stable and safe.

Purlins are usually made of steel or aluminum. They carry the roof’s weight to the main beams, like rafters or trusses. This prevents heavy loads from damaging the roof, even under snow.

Definition and Basic Functions

Purlins are horizontal beams that:

- Support roof decking and roofing materials

- Distribute loads evenly across the building’s frame

- Provide critical structural support for metal roofing systems

- Enhance the overall stability of the roof structure

Historical Evolution of Purlin Usage

Purlins have evolved to meet roofing needs. They’ve moved from simple wooden supports to modern steel sections. This change has greatly improved roof design and construction.

| Purlin Type | Material | Load Capacity |

|---|---|---|

| C-Purlins | Steel | Standard Load |

| Z-Purlins | Steel/Aluminum | Heavy-Duty Load |

Role in Modern Construction

In modern building, purlins are vital for flexible designs. They allow for longer spans, better energy use, and strong environmental protection. Modern purlins can extend spans up to double, keeping the structure strong.

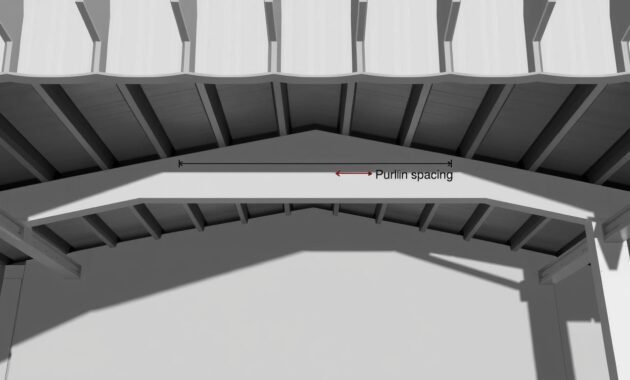

Metal Roof Purlins Spacing: Essential Guidelines

Installing a metal roof sheet requires knowing the right purlin spacing. This knowledge is key to a strong roof. My roofing experience shows that proper spacing is vital.

The spacing of purlins depends on several important factors. Residential roofs need different spacing than commercial or industrial ones. Here are the main points to consider:

- Residential roof purlins are usually spaced 24″ to 30″ on center

- Commercial buildings can extend purlin spacing up to 5 feet

- Roof pitch significantly impacts optimal spacing

When figuring out purlin spacing, keep these guidelines in mind for metal roof sheet installation:

| Roof Characteristics | Recommended Spacing | Considerations |

|---|---|---|

| Low Pitch (3:12 or less) | 18″ minimum | Requires closer support |

| High Snow Load Areas | Reduce spacing | Accommodate additional weight |

| Large Buildings | Up to 32″ | Depends on steel gauge |

The heavier the load, the closer purlins should be. Always check local building codes and talk to a structural engineer. They can help find the best spacing for your project. This ensures your metal roof stays strong and secure for many years.

Remember, it’s not just about following rules. It’s about building a solid roof that can handle different weather conditions.

Load Distribution and Structural Support Fundamentals

Understanding how loads are distributed is key to a strong metal roof. Purlins help move roof loads across the building’s structure. The way loads are spread out affects the roof’s strength.

When designing a metal roof, engineers must figure out load needs. This ensures the roof is safe and affordable. Different loads affect how purlins are spaced and supported:

- Dead load (permanent structural weight)

- Live load (temporary loads like maintenance personnel)

- Wind load

- Snow load

- Seismic load

Weight Distribution Mechanics

Shorter load spans help distribute weight better. C steel purlins are made to manage loads evenly. The right size ensures loads are spread out right across the roof.

| Load Type | Characteristic Value | Impact on Purlins |

|---|---|---|

| Dead Load | 0.934 kN/m | Permanent structural weight |

| Wind Load | 1.0 kN/m² | Horizontal pressure distribution |

| Snow Load | 1.0 kN/m² | Vertical downward pressure |

| Live Load | 1.0 kN/m² | Temporary human activity load |

Support Requirements for Different Loads

Purlins need precise engineering to handle different loads. Wrong sizing can be risky. Knowing load types helps design a strong, lasting roof.

Impact of Spacing on Structural Integrity

Right purlin spacing is vital for roof strength. Material strength, weather, and expected loads guide spacing. Smart design balances safety, durability, and cost.

Types of Metal Purlins: C-Purlins vs Z-Purlins

When it comes to metal roofing, C-purlins and Z-purlins are the top choices. As a construction pro, I’ve worked with both. Let me explain their differences to help you choose.

C-purlins are the most common. They have a 90-degree angle and are used in many projects. Their simple design makes them easy to install. They can be roof, wall, or even floor beams.

Z-purlins are for more complex roofs. They have an angle less than 90 degrees, making them stronger. Here’s why Z-purlins are great:

- They can save up to 50% on structural sheets

- Perfect for roofs with big slopes

- Great for strong buildings like farms and factories

- They help support the roof better

Choosing between C and Z purlins depends on your roof’s slope, load, and support distance. Both are made of galvanized steel for lasting durability.

The right purlin can make your building last longer and work better. C-purlins are simple and easy to put in. Z-purlins are better for strong support and longer spans.

Read also: How to Overlap Metal Roofing?

Purlin Installation Best Practices

Installing purlins right is key for a strong roof deck. As a roofing pro, I’ve seen how proper installation helps manage roof weight. It also prevents structural failures.

- Check the roof for damage or issues

- Make sure rafters and support are aligned

- Have all tools and materials ready

- Know if the structure can hold the load

Essential Installation Techniques

Here are the main techniques for installing purlins:

- Use the right lap length (15% of the span)

- Support joins and laps with rafters

- Keep bridging spacing right (max 20 times purlin depth)

- Use at least one row of bridging per span

Common Installation Mistakes to Avoid

Here’s a quick guide to avoid common purlin installation mistakes:

| Mistake | Consequence | Prevention |

|---|---|---|

| Insufficient lap length | Structural weakness | Maintain minimum 15% lap length |

| Improper spacing | Uneven load distribution | Follow recommended spacing guidelines |

| Hot cutting or welding | Potential stress concentrations | Avoid modifications that compromise integrity |

By sticking to these best practices, you’ll get a strong purlin installation. Remember, careful prep and detail are essential for success.

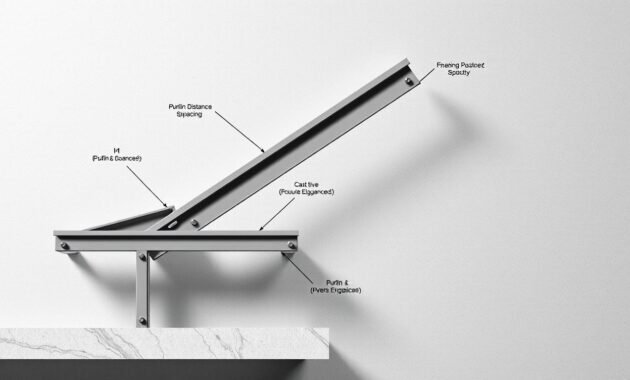

Rafter Distance Calculations and Considerations

Getting the rafter distance right is key for a solid metal roof. As a roofing pro, I’ve seen how accurate measurements are vital. They ensure your project is both strong and cost-effective.

Several factors influence rafter spacing. For homes, purlins usually go 600 to 800 mm apart. This spacing is critical for your roof’s performance.

- Maximum purlin distance should not exceed 1200 mm for steel structures

- Sheathing thickness affects maximum spacing (7 mm can reach 1200 mm, 5 mm limited to 1000 mm)

- Depth of purlins can be estimated using the rule: depth = span/32

I suggest a simple way to find the best rafter distances. The depth of your purlins is key in supporting the roof. For example, cold-formed steel purlins are great at handling loads and keeping things stable.

When designing on a budget, think about load combinations. These include:

- Dead Load only

- Dead Load + Live Load

- Dead Load + Wind Load

- Dead Load + Wind Load + Live Load

Professional tip: Always check local building codes and think about weather like snow and wind. The right numbers can save you a lot of time and money.

Material Selection for Purlins

Choosing the right material for purlins is key to a good roofing system. It affects how long it lasts, how well it works, and the cost. The right choice can save money and make your project better.

Galvanized Steel Options

Galvanized steel is a top pick for purlins. Its zinc coating fights off rust, making it great for tough weather. Steel purlins bring many benefits:

- Resistant to rot and moisture

- Minimal expansion in varying climates

- Non-combustible safety features

- Potential lifespan of 50+ years

Aluminum Alternatives

Aluminum purlins are another option for certain projects. They are light and resist corrosion well. But, there are things to think about:

- Lower weight compared to steel

- Suitable for regions with moderate environmental stress

- Potentially higher initial cost

Material Performance Comparison

| Property | Galvanized Steel | Aluminum |

|---|---|---|

| Durability | 50+ years | 30-40 years |

| Corrosion Resistance | Excellent (zinc coating) | Good |

| Cost Effectiveness | High | Moderate |

| Weight | Moderate | Lightweight |

Think about your project needs before deciding. Galvanized steel is strong and cost-effective for most projects. But, consider the weather, your budget, and how long you want it to last. This will help you choose the best material.

Weather and Environmental Impact on Purlin Spacing

Designing a metal roof needs careful thought about environmental challenges. Weather conditions are key in setting the right purlin spacing and roof strength. It’s vital to know how snow loads, wind, and local climate affect roof design for lasting performance.

Roof engineers must think about many environmental factors when figuring out snow loads and roof weight. The heavier the load, the more important proper purlin spacing is. Each region has its own challenges that need a special roof design approach.

Snow Load Considerations

Roof design must handle snow well. Important things to consider are:

- Where you are and how much snow falls

- The roof’s slope and surface

- How snow might not spread evenly

Wind Resistance Requirements

Wind resistance is key to keeping the roof strong. Miami-Dade County shows strict wind standards for roofs:

| UL Classification | Uplift Resistance | Pressure Rating |

|---|---|---|

| Class 30 | Minimal Resistance | 45 psf |

| Class 60 | Moderate Resistance | 75 psf |

| Class 90 | High Resistance | 105 psf |

Climate-Specific Adjustments

Different climates need special roof designs. Things like temperature, rain, and wind affect purlin spacing and material choice. Builders must adjust their designs for local weather to ensure the roof lasts long and works well.

Knowing these environmental effects helps make smart choices about purlin spacing. This protects your building from various weather challenges.

Maintenance and Inspection Guidelines

Keeping your metal roof in good shape is key for its long life and saving money. Regular checks can stop small problems from turning into big, costly fixes. Here’s how to keep your purlins in top shape.

Experts say you should check your roof at least twice a year. These checks are vital to catch issues early. Look closely at:

- Corrosion signs on purlins

- Loose or missing fasteners

- Potential water damage

- Flashing integrity

When inspecting your roof, safety comes first. The Bureau of Labor Statistics found 647 fatal roof falls in 2014. If you’re not sure about inspecting, it’s better to hire a pro.

After a big storm, it’s even more important to check your roof. Storms can damage your roof in ways you can’t see. Watch out for:

- Visible dents or punctures

- Displaced or loose purlins

- Water stains on interior ceilings

- Rust or corrosion patches

With regular care, your metal roof can last longer and save you money. Always fix problems before they get worse.

Building Code Compliance and Standards

Understanding building codes for metal roof purlins is key for a successful roofing project. The load is a critical factor in determining purlin spacing and structure needs. Most U.S. areas follow the International Building Code (IBC) and International Residential Code (IRC). These codes offer detailed guidelines for installing metal roof sheets.

- Wind exposure categories

- Roof structure evaluation requirements

- Fire resistance classifications

- Geographic-specific environmental loads

The 2018 International Building Code introduces more detailed roof zones for wind and snow loads. About 60-80% of buildings face Exposure B wind categories. This greatly affects purlin design and spacing. Roof assemblies must also meet fire-resistance ratings – Class A, B, or C. Class A offers the highest protection.

When planning a metal roof installation, it’s wise to consult local building authorities and engineers. They can ensure your project meets all standards. This is important in areas with unique environmental challenges like hurricanes or heavy snow.

Professional tip: Always check that your metal roof sheet and purlin system follow local building codes. Requirements can vary a lot between different places.

Conclusion

Exploring metal roof purlins spacing has shown me how important precision is. The strength of your roof depends on where you place the purlins. You must think about many factors.

Every project is different, and no one solution works for all. The location, shape of the roof, and materials used are key. Steel purlins are great because they hold tight and can be installed in various ways.

Getting expert advice is essential. Talk to structural engineers to figure out the right spacing for fasteners. They ensure your roof lasts long and stays strong against the weather.

Don’t just focus on following codes. Proper metal roof purlins spacing makes your roof strong and safe. It protects your property for many years.