Many people often ask about plywood thickness for roofing. Plywood is not a very popular choice. Many homeowners still prefer to use good old-fashioned clay shingles or metal roofing for the job.

However, if you choose plywood, you must understand the minimum thickness of the roofing purpose. The full information about it is explained below.

Read also: How to Repair Granular Loss on Roof

Plywood Thickness for Roofing

Many people ask about roof decking and plywood thickness. Plywood is not a very popular choice for roofing. Many homeowners still prefer to use good old-fashioned clay shingles or metal roofing for the job.

However, if you choose plywood, you must understand the minimum thickness of the roofing purpose. The full information about it is explained below.

- Lightweight

Plywood is considered lightweight, especially compared to metal roofing or clay shingles. It adds fewer burdens to the house’s structure and helps keep the roof together for a longer time.

- More Affordable

Among all types of roofing material, plywood is probably the cheapest one. It is because plywood is like a recycled timber material with great quality, but it is widely available worldwide. It makes the price really cheap and more budget-friendly.

- Flexible in Design

Plywood is better when it comes to design. It can be used for any building type, from rustic to contemporary. You can also color it as you like, as plywood absorbs painting material quite easily.

- Thermal Insulation Advantage

Plywood does absorb heat, but not as much as metal roofing. It adds warmth to the rooms and halls under the roof, which is why plywood is such a good insulation agent for those who live in colder areas.

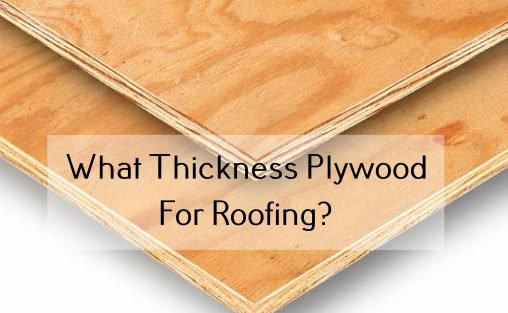

What Thickness Plywood is Used for Roofing?

Now, it is time to figure out the roof sheathing thickness for roofing. Basically, there is no setting stone for this. However, these thicknesses are just the most common ones. They do become the standard when people use plywood as the material for their roofing selection.

| Roofing Type | Minimum Thickness | Recommended Thickness | Notes |

|---|---|---|---|

| Flat Roof | 18mm (0.709 inches) | 18mm (0.709 inches) | Ensure staggered joints for improved structural integrity. |

| Standard Roof (Asphalt Shingles) | 3/8 inch | 5/8 inch | Adequate for residential roofing with 16-inch rafter spacing. |

| Metal Roof | 1/2 inch | 3/4 inch | Supports additional weight and prevents sagging. |

| Low-Slope Roof | 1/2 inch | 3/4 inch | Provides extra protection against water pooling. |

- The Minimum Thickness

Based on professional experience, the minimum plywood thickness for flat roofs should be 18mm (approximately 0.709 inches). This thickness ensures the structural stability to support the roof covering and resist potential load stresses.

As a practical note, a staggered joint layout is recommended to enhance the overall integrity of the roofing structure.

According to various experts, 3/8-inch plywood is adequate for residential roofing with rafters spaced at 16 inches, but thicker sheathing is advisable in regions with heavy snowfall or high winds.

- The Most Common Thickness

Commonly, ¾-inch plywood is used in commercial buildings due to its ability to support substantial loads, including snow and debris, without compromising the roof’s structure. For metal roofs or low-slope roofs, however, a thickness of 3/4 inch is also recommended due to the additional weight and potential for water pooling, which thicker plywood can mitigate effectively.

In high-load situations, such as regions prone to heavy snowfall, increasing the plywood thickness is strongly advised to prevent sagging and maintain the roof’s durability over time.

It all starts by choosing the right plywood thickness for roofing.

In addition to plywood, oriented strand board (OSB) is another popular material used for roof decking. It consists of layers of wood strands bonded together with adhesives. The choice between plywood and OSB often depends on cost, durability, and local building codes.

When installing roofing plywood, consider the spacing between rafters, the roof’s slope, and the load it will bear. If your roof has a low slope, or if it will bear heavy loads such as snow, it’s crucial to opt for a thicker plywood sheathing to prevent warping or sagging.

It’s also essential to leave expansion gaps of about 2-3mm between the sheets to accommodate any expansion or contraction due to weather conditions.

Experts also recommend using high-quality fasteners to ensure your roof’s long-term stability and safety.

Roof Support and Spacing

When installing plywood for roofing, it’s important to consider the spacing of the roof supports. Typically, roof supports are spaced 16 inches apart, but this can vary depending on the types of roofs and the specific requirements of the building structure.

Now, you have read almost everything related to the thickness. When you have decided to go with plywood for the roof, you can choose the best material and the standard thickness so that the roof will be installed on the top of the house for decades without being replaced too often.