In the discourse of civil science and architecture, how to build a shed roof is a monumental part that must be considered and considered carefully. Such attention and consideration lead to the form and material to be used. Light steel is a popular choice for roof-style construction due to its numerous advantages over traditional materials.

This is inseparable from the advantages of lightweight steel construction compared to conventional constructions. For various reasons, steel is an ideal construction medium for warehouses and other industrial buildings.

From my experience, steel construction’s lightweight nature significantly eases transportation and installation. When building my own shed, I found that the lightness of the steel not only reduced transportation costs but also made the assembly process faster and safer, especially compared to heavier materials like wood or concrete.

Having a lightweight and the potential for a small dead load does not reduce the tensile strength. This makes lightweight steel construction suitable for roof design structures, especially spans of quite wide construction.

Read also : How To Install Roof Anchors

Because it is a factory-made product, light steel construction is consistent in quality. This helps to create precise structures when building or renovating houses and sheds. In addition to being economical and durable, steel provides the simplest solution for building designs requiring large open spaces and significant design flexibility.

This article will delve into the nuances of building a shed roof from light steel, considering various architectural styles, including saltbox roofs and gambrel roofs.

During my construction process, I discovered that the style and pitch of the roof significantly impact the choice of materials. For example, a steep pitch (above 20 degrees) is ideal for heavy concrete interlocking tiles, which provide excellent durability, as I observed while building a gable roof for my garden shed.

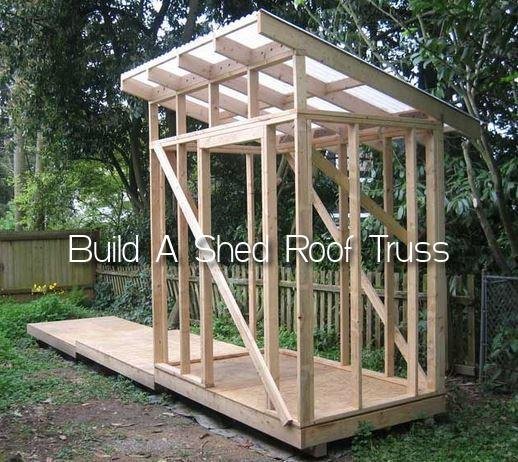

Build A Shed Roof Truss with Light Steel Construction

A roof truss is a systematic structure that supports a building or residence. In other words, it is a form (frame) that makes it stable and also connects and stabilizes the bottom of the building (foundation). Sheds with a conventional form have a roof frame with proportions that fit differently from old houses, usually lacking a proportional roof frame.

After the Industrial Revolution made steel popular, the wooden roof truss was replaced by an iron roof truss. The iron roof frame is more durable and fire-resistant. At present, both wood and iron materials have progressed in terms of quality.

Durability is no longer the main reason for building a shed roof and choosing a frame from certain materials. Interior design trends and the effects become more valuable for the iron roof truss, both technical and aesthetic.

If your company plans to build a warehouse, especially a shed roof truss, use a steel frame because the cost of building a steel frame warehouse is more effective. Individuals widely use this steel frame in building houses or companies with the cost of building a more economical steel frame warehouse.

When building my shed with light steel trusses, I found the process remarkably efficient. Unlike traditional wood construction, the steel trusses provided cost savings and structural stability. This aligns with recommendations that trusses, though requiring more planning, offer long-term savings in both time and material costs.

Build A Shed Roof Over A Deck

In rehabilitation and renovation work, adding or changing must be done under new functions or living needs. Therefore, excessive loads on building structures should be avoided, and roof truss structures should be made as light as possible.

Building a shed roof requires a lightweight iron frame, pillars, and iron plates, which are highly recommended. Simultaneously, other materials, such as wood and partitions, can be selected according to their respective weights.

Lightweight steel horses’ installation on the supporting structure (column or ringbalk) must be carried out correctly and carefully so that the lightweight steel roof truss is installed following its requirements.

- The technical requirements for lightweight steel roof truss include:

- The horses are mounted strong and stable, equipped with anchors (dynabolt) on both sides.

- All sawhorses are perpendicular to the ringbalk.

- The height of the apex for mounting the rooftop above each

- Flat sawhorses.

- Sloping roof flat (not bumpy)

- No damage to the protective coating

- No deformation (change of form) due to an error in the performance of the work.

The installation of light steel horses on both supports can be done in two ways, namely :

- Installed directly above the ringbalk.

- Mounted on a ringbalk with a wall-plate intermediate.

The use of a pedestal system with a wall plate, wherever possible, may have to be avoided because the wall-plate support is only intended for leveling (ringing) the ringback if the ringback is uneven. The use of wall plates will reduce the depth of the dynabolt embedded in the ringback. Besides, a space in the wall plate can cause horses’ placement to be less stable.

In my experience, it is crucial to ensure the proper installation of waterproof underlay when working with low-pitched roofs (10-20 degrees).

Failure to do so can lead to water ingress, especially during heavy rains. High-quality materials like bitumen felt, paired with adequate ventilation, prevent such issues.

| Roof Style | Pitch (Degrees) | Recommended Material | Key Considerations |

|---|---|---|---|

| Flat Roof | 0-10 | Bitumen Mineral Felt | Requires frequent maintenance to prevent leaks; ensure a minimum pitch for longevity. |

| Low Pitch Roof | 10-20 | Tiles and Shingles | Use waterproof underlay; essential for water resistance against wind-driven rain. |

| Steep Pitch (Pitched) | 20+ | Concrete Interlocking Tiles, Clay Tiles | Best suited for higher pitches; consider weight on the structure. |

| Eco-Living Roof | Any | Green Roof Felt, EPDM | Attractive and low-maintenance; ideal for modern shed designs. |

Building A Shed Roof with Overhang

It differs slightly from the general shape for building a shed roof, especially with overhang roofs. Overhang roof edges are needed to block heat from the sun and splashes of rain that might enter and damage property at home.

Architecture in the East often has a longer roof overhang than in the West, especially in Southeast Asia. In the East, the edge of the overhanging roof is needed to block the heat from the sun and the splash of rain that might enter and damage the items in the house.

The principle for designing a roof that stretches further than usual is to create a balancing force between structures in reaction and action. There is no need to design symmetrical shapes because balance can come from the action force’s detail. However, it is possible to design columns large enough together with structures to support the roof rafters.

With this principle, how do you build a shed roof, especially overhangs? The roof can seem to hang as if it fell on the stadium roof. In this case, understanding detail means understanding structural behavior.

When the roof’s edge protrudes more than normal without the need for purlin, understanding the structure can provide new adaptations, such as allowing a bracket to support the rafters’ bottom. Then, distribute the heavy load to the column poles. For durability and beauty, focus on the design of wire ropes that secure or support the rafters.

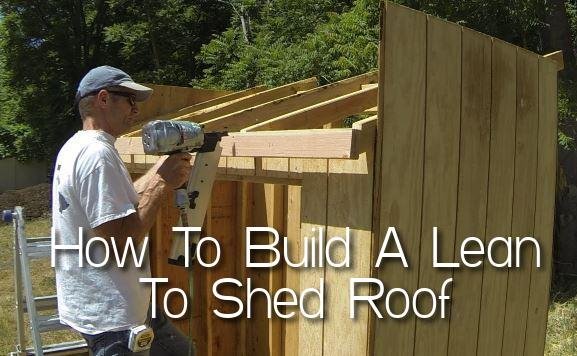

How To Build A Lean To Shed Roof

The most popular basic form of roofing is the roof of the pyramid (hip roof), gable roof, flat roof, and shed roof. The first three forms are relatively more plural than the last. More lean roofs were applied to warehouses, cabins, and the like.

Most residential homes applied to additional buildings attached to the main building, such as a terrace, hallway, or garage. Lately, however, this simple roof has been widely applied to major buildings such as minimalist and modern dwellings.

Actually, how to build a shed roof with a leaning roof – with the basic form of one side sloping – is not much different from the work of the gable or the pyramid (shield).

After the wall, plastering, and action installation work is finished, the horses’ installation can be carried out, followed by the parts of the roof truss (roof beams, gorging, rafters, and battens) to the type of roof coverings. The final stage is installing the roof cover, followed by finishing.

However, special considerations need to be made when building a leaning roof, especially regarding wall construction and/or roof truss. The horses (½ horses) can be replaced with the grooms—the structure above the wall supporting the roof.

For edges of buildings exposed to and affected by outside weather, the structure above the wall supporting the roof should be used. However, for the construction of a shed roof in the middle (if the building is wide enough), the type of horses that will be the foundation of the rooftop beam (cam) and gorging on that part must be determined.